A Cylindrical Battery Double-Sided Spot Welding Machine is an advanced piece of equipment designed for high-precision, automated welding of cylindrical lithium batteries. It is ideal for welding applications in various battery-powered devices, including:

Consumer electronics (e.g., digital batteries)

Power tools

Electric bicycles and scooters

Solar energy systems

Electric vehicles (EVs)

Medical devices

Drones and aviation models

This machine is specifically tailored for cylindrical batteries such as 18650, 21700, 26650, 32650, and other similar types, ensuring consistency, reliability, and efficiency in battery pack production.

Key Features and Performance

Real-Time Current Monitoring

Fault Detection with Alarms

Selective Start Welding

One-Time Origin Alignment

Fast Welding Time

Customizable Welding Skip Function

Enhanced Durability and Cooling

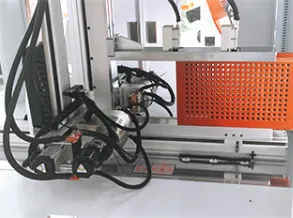

Simultaneous Double-Sided Welding

User-Friendly Interface

Safety and Mobility

How to Use It

Setup

Place the machine on a stable surface and adjust the leveling feet as needed.

Align the battery pack with the welding head, using the touch screen interface to set parameters.

Configuration

Set welding voltage, current, and energy standards to match battery specifications.

Use the skip function for specific cells if required.

Operation

Cleaning and Maintenance

Automated Process Flow

Battery packs are loaded into the machine.

The system detects and aligns cells for welding.

Simultaneous welding of positive and negative terminals occurs.

The machine performs real-time quality checks and flags anomalies.

Completed battery packs are unloaded, ready for subsequent assembly steps.

Benefits of the Cylindrical Battery Double-Sided Spot Welding Machine

Improved Efficiency

Enhanced Precision

Cost-Effective

Operator Safety

Wide Applicability

Important Considerations

Battery Compatibility

Regular Maintenance

Parameter Calibration

Conclusion

The Cylindrical Battery Double-Sided Spot Welding Machine is an indispensable tool for modern lithium battery production. It combines precision, efficiency, and automation, ensuring reliable performance for a wide range of battery applications. Whether you’re manufacturing EV batteries, medical device batteries, or energy storage systems, this machine optimizes your production line and guarantees consistent quality.